Brightworks industrial design team initially worked with XMOS to develop several generations of demonstration units for exhibition display and later for sales & marketing purposes. This development work included the design of a number of hand held gaming controllers.

Brightworks industrial design team initially worked with XMOS to develop several generations of demonstration units for exhibition display and later for sales & marketing purposes. This development work included the design of a number of hand held gaming controllers.

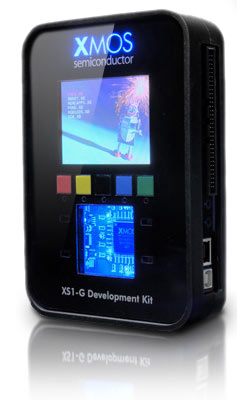

Following on from the success of this initial work, the product design team at Brightworks went on to design a custom enclosure for the XDK (xCORE development kit).

The XDK enclosure was to be produced in higher volumes and had to be highly customisable; to enable it to be used in a wide variety of different configurations and contains different hardware components to suit the extremely wide variety of potential uses for the novel microcontroller circuitry.

Brightworks designed the custom enclosure so that the product could be configured in many different ways depending on the requirement; the board has several different mounting positions and the enclosure can accommodate several different sizes of display. The enclosure uses laser cut panels on all 6 sides, which may be metal or plastic, profiled for connectors & buttons or just plain, clear, opaque or reverse screen printed. These panels can simply slot into place, providing an extremely quick and robust construction - the final assembly being completed by 4 self tapping screws.

Brightworks produced several stereolithography (SLA) prototypes and then a short run of working prototypes with vacuum cast Polyurethane (PU) enclosures, from soft silicone tooling, for initial trials and user evaluation. The prototypes proved the design to be a success so Brightworks detailed the simple 2 part enclosure for injection moulding and liaised with a Far East manufacturer to produce a low cost tool and the first batch of production enclosures.

|