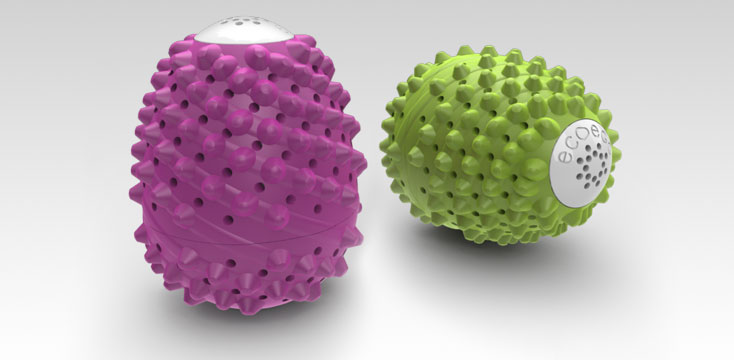

| Tumble Dryer Ball

The Dryer Egg is a simple device that reduces the time it takes to dry clothes in a tumble dryer - saving consumers’ time and electricity and ultimately providing considerable savings and helping the environment.

Wet clothes naturally clump together in a tumble dryer and the dryer eggs helps to lift and separate the clothes inside the drum. This means that the air can more readily move around the clothes and so dry them more quickly.

The nodules on the outside of the eggs are specially designed to gently lift the fibres, helping to reduce stiffness created by washing and gently softening the clothes naturally without the use of chemical fabric softeners.

The egg further contains a heat activated fragrance sticks which gently infuses a delicate scent into the clothes without involving any harsh chemicals.

|